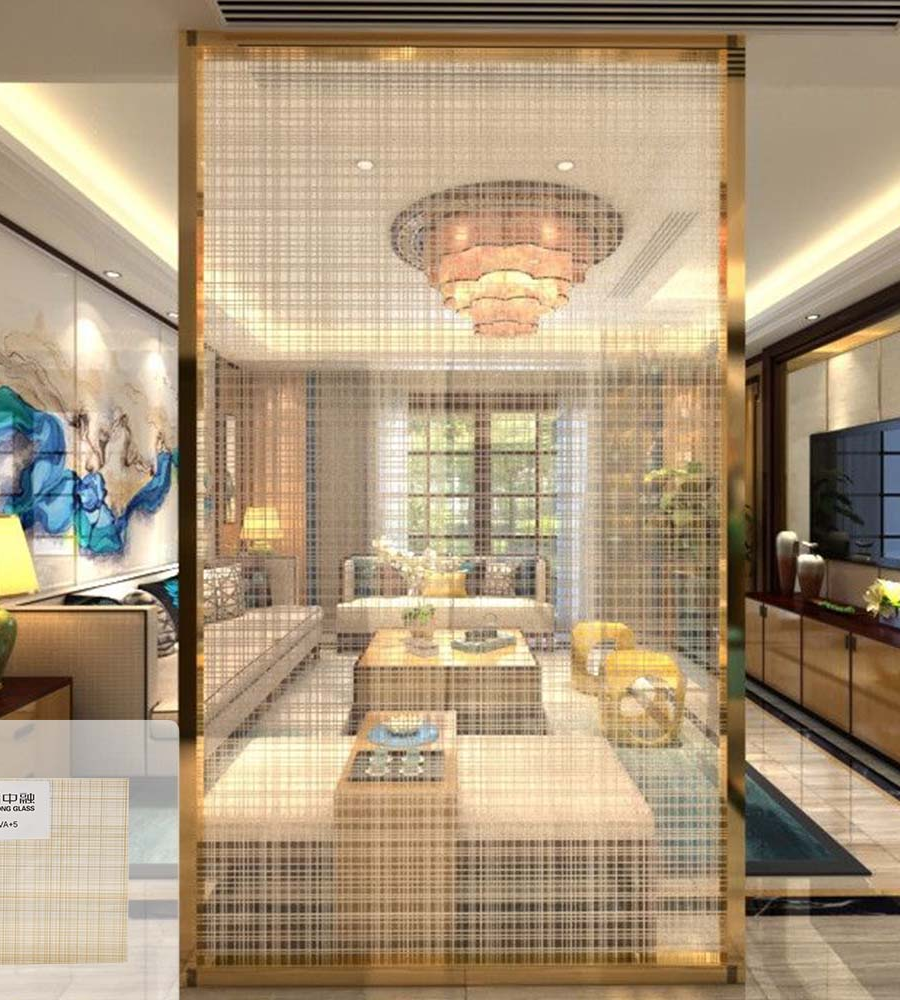

Safety is just another term to describe ZRGlas’ laminated glasses , they are also attractive because they can be produced using different colors as well as patterns depending on client’s design needs. Be it modern minimalistic style or traditional retro style you will find your desired laminate glass here.

Laminated glass technology has been the domain of ZRGlas, a prominent glass brand in the market. Their laminated glass products go beyond safety and durability but also provide modern architectural designs with innovative solutions. With their state-of-the-art manufacturing facilities, they are able to make laminated glasses that meet the highest quality standards as well as performance.

Laminated glasses are used as security reinforcements in building envelopes, which provide resistance against forced entry and vandalism. By its tough interlayer materials that make it hard to penetrate, laminated glasses restrict unauthorized access thus deterring intruders. ZRGlas offers a variety of different types of laminated glass with different levels of security features that cater for various residential, commercial or institutional building needs.

Laminated glass is popular because of its high safety standards; it is used where safety and security are utmost. It comprises two or more layers of glass bonded together using a polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) interlayer, hence remains whole even after breaking thereby minimizing chances of injury from sharp pieces of glass. ZRGlas has prioritized the safety in their laminated glasses which they offer without compromising on the quality as well as aesthetics.

Architects and designers looking for unique visually striking spaces have many options in terms of design when they use laminated glass due to its decorative possibilities other than functional purposes it serves as partitioning elements. The versatility of laminated glass allows for innovative design solutions to be implemented in several projects; ranging from decorative glass partitions and balustrades to laminated glass floors and ceilings. ZRGlas works with customers to create custom laminal designs that reflect their unique vision and style.

Zhongrong Glass , , established in 2000, is a modern enterprise specializing in the deep processing of architectural glass. With over 20 years of development, we have built four major production bases in Foshan, Guangdong, Chengmai, Hainan, and Zhaoqing, Guangdong, covering a total area of 100,000 square meters.

Adhering to the spirit of "Goodwill, Integrity, Integration, and Connectivity," Zhongrong Glass is dedicated to innovation, incorporating internationally leading intelligent equipment. Our glass products, distinguished by unparalleled processing technology and professional expertise, excel in aesthetics, environmental friendliness, and energy efficiency.

Zhongrong Glass, committed to excellence in quality and service, meets diverse demands as your trusted architectural partner. We provide innovative products, reliable services, valuable suggestions, and professional support. Join hands with Zhongrong Glass to create a brilliant future together.

Our company has extensive experience in Low-E glass tempering processing, as well as world-leading first-class glass deep processing equipment, and as many as 65 mainstream Low-E film systems in the market to choose from.

There are 4 major production bases across the country, covering an area of about 100,000 square meters, and have advanced intelligent software systems.

ZRGlas prides itself on delivering products of the highest quality, ensuring that every item meets stringent standards for reliability and durability.

ZRGlas boasts a team of highly skilled and experienced professionals, who bring their expertise to bear in crafting top-notch products.

Our laminated glass products range in thickness from 6.38mm to 42.3mm.

Yes, we can produce laminated glass in a variety of sizes to meet your specific requirements.

Our laminated glass is certified by ISO 9001 and meets the standards of EN 12543 and ANSI Z97.1.

Yes, our laminated glass is designed to withstand high temperatures and is suitable for various environments.